In CNC gear production plant, over ten of gears making lines:

broaching , we’ve made substantial investment..

Our high precision equipment can keep a high quality prodcuts.

Can do all of the heating process: Carburizing/Carbonitriding/Quenching/normalizing/annealing/Reheating

2 sets of German Ipsen atmosphere furnace lines.

9 ton of steel ability for heat treatment per day.

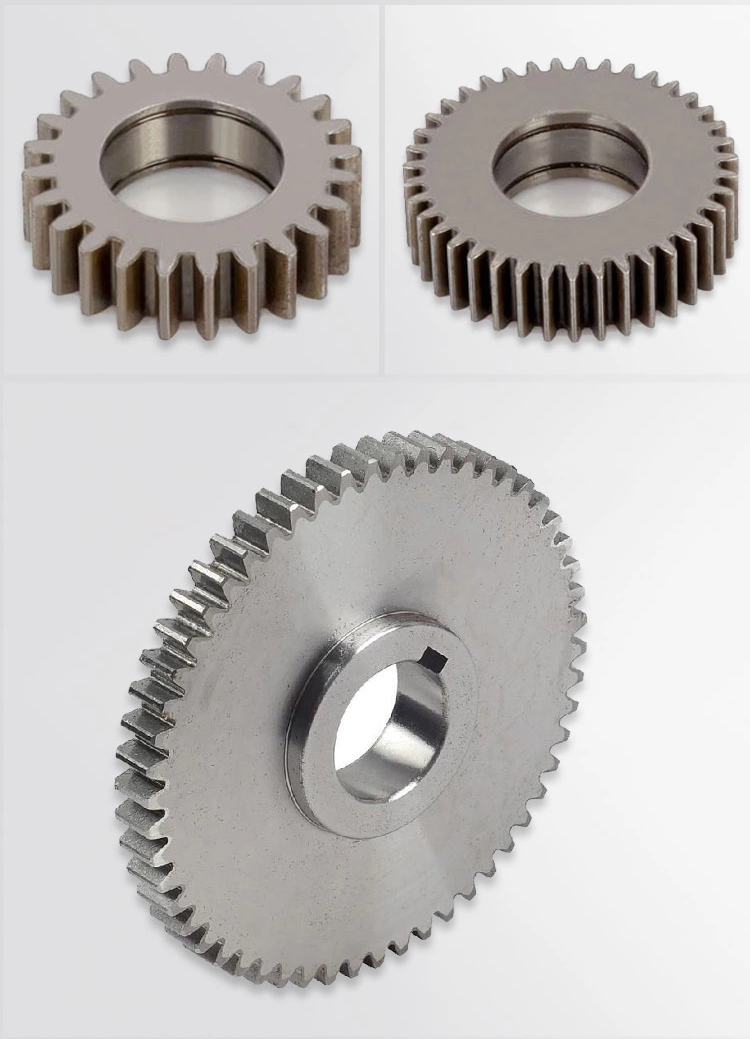

Spur Gear for Machines

The gear is widely used in industry, vehicle, power tools, motor, bicycle, electrombile.

Small Module Precision Spur Gear

China car pinion spur gear factory

low carbon steel metal gears small,small steel metal spur gears!

From simple 2-axis turning to 7-axis, turn-mill-drill CNC Swiss-type machines, we are equipped with a full line of CNC equipment from the following manufactures:

molding machines/ stamping machines

automatic lathe machines/ spring machines.

Surface: as your requirement

Our Cleanses

2.Sprockets can be made according the customer’s drawings

3.Heat treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on according the requirements..

4. Inspection: All items are checked and tested thoroughly during every working procedure and after production will be reinspected.

Gear transmission refers to the device that transmits motion and power from the gear pair. It is the most widely used mechanical transmission method in modern equipment. Its transmission is more accurate, high efficiency, compact structure, reliable operation and long service life.

Our gears can be heat treated, hardened, oil immersed according to customer needs.

The gear is widely used in industry, vehicle, power tools, motor, bicycle, electrombile.

High Precision Custom Spur Helical Gear

Spur gears are widely accepted as the most efficient type of gearing solution, when the application of transmitting power and uniform rotary motion from one parallel shaft to another is required. Determined by the center distance, spur gears create a steady functioning speed drive. This drive speed can be decreased or increased by the variable number of teeth that exist in the driving gear.

Type: Bevel Gear

Manufacturing Method: Cut Gear

Toothed Portion Shape: Bevel Wheel

Main Customer: Electric tool factory

Export Markets: Global

small pinion steel double spur gear

Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing,

Electroplating, anodizing etc.

Black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic,

Contact Us

We can make customers’ satisfactory products according to the samples or drawings provided by customers. For the completion of a product, we also need to know his material, heat treatment requirements and surface treatment requirements. We are a factory with 40 years of manufacturing experience, welcome to consult.

Website

www.spur-gears.com