Product Description

Product Description

Cylindrical Custom Drive Transmission Machine oil pump Cog-Wheel Helical Spur Gear

| Item | Customized machined machining gears | |

| Process | CNC machining,CNC milling, cnc lathe machining | |

| material | steel, stainless steel, carbon steel,brass,C360 brass copper, aluminum 7075,7068 brass,C360 brass copper, aluminum Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spur gears be used in automotive applications?

Yes, spur gears can be used in automotive applications. Here’s a detailed explanation:

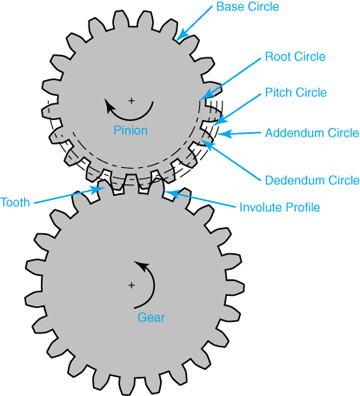

Spur gears are one of the simplest and most commonly used types of gears. They consist of cylindrical teeth that are parallel to the gear axis and mesh with each other to transmit power and motion. While other gear types like helical gears or bevel gears are often preferred in certain automotive applications, spur gears still find their place in various automotive systems and components.

1. Transmissions:

Spur gears are commonly found in manual transmissions, especially in lower gears. They are used to achieve a direct and efficient power transfer between the engine and the wheels. Spur gears in transmissions are designed to handle high torque loads and provide reliable performance.

2. Differential:

In automotive differentials, which distribute power between the wheels while allowing them to rotate at different speeds, spur gears are often employed. They are used in the differential gear train to transfer torque from the driveshaft to the wheels. The simplicity and robustness of spur gears make them suitable for this application.

3. Starter Motors:

Spur gears are commonly used in starter motors to crank the engine when starting a vehicle. They provide high torque and efficient power transmission to rotate the engine’s crankshaft and initiate the combustion process. Starter motor spur gears are designed to handle the initial load and engage smoothly with the engine’s flywheel.

4. Timing Systems:

In automotive timing systems, where precise synchronization of engine components is crucial, spur gears can be used. They are employed in timing belts or chains to drive the camshafts, ensuring proper valve timing and engine performance. Spur gears in timing systems contribute to accurate and reliable engine operation.

5. Accessories and Auxiliary Components:

Spur gears are also utilized in various automotive accessories and auxiliary components. They can be found in power window mechanisms, windshield wipers, power steering systems, and other mechanisms that require controlled and synchronized motion. Spur gears provide cost-effective and efficient power transmission for these applications.

It’s important to note that while spur gears have their advantages, they also have certain limitations. They can generate more noise and vibration compared to gears with helical or bevel tooth profiles. Additionally, spur gears are not as suitable for high-speed or high-torque applications as other gear types.

Overall, spur gears have a significant presence in automotive applications, particularly in manual transmissions, differentials, starter motors, timing systems, and various auxiliary components. Their simplicity, reliability, and cost-effectiveness make them a viable choice for specific automotive gear applications.

What are the advantages and disadvantages of using spur gears?

Spur gears offer several advantages and disadvantages when used in mechanical systems. Here’s a detailed explanation of the advantages and disadvantages of using spur gears:

Advantages of Spur Gears:

- Simplicity: Spur gears have a simple and straightforward design, consisting of cylindrical gears with straight teeth. Their simplicity facilitates ease of manufacturing, installation, and maintenance.

- Efficiency: Spur gears are highly efficient in transmitting power from one shaft to another. They have minimal sliding friction between the gear teeth, resulting in high mechanical efficiency.

- Cost-Effectiveness: Due to their simple design and ease of production, spur gears are generally more cost-effective compared to other types of gears. They are widely available and can be manufactured in large quantities at a reasonable cost.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in parallel or stacked configurations to achieve the desired gear ratios within a confined space.

- High Load Capacity: Spur gears can handle high load capacities and transmit substantial amounts of torque. Their teeth are designed to distribute the load evenly across the gear face, resulting in improved load-bearing capabilities.

- Precision: Spur gears provide precise and predictable motion due to the simplicity of their tooth engagement. This makes them suitable for applications that require accurate positioning and synchronization.

Disadvantages of Spur Gears:

- Noisy Operation: Spur gears can produce noise during operation, especially at high speeds. The engagement of the gear teeth generates impact and vibration, resulting in noise that may require additional measures to mitigate.

- Axial Thrust: Spur gears generate axial thrust forces along the gear shafts due to the parallel arrangement of their teeth. This thrust must be properly managed using thrust bearings or other means to prevent excessive axial loading on the gear shafts.

- Limited Speed Ratio: Spur gears are primarily designed for applications with moderate speed ratios. They are less suitable for high-speed applications due to the limitations imposed by the tooth engagement and potential for increased noise and vibration.

- Unidirectional Operation: Spur gears are typically designed for unidirectional power transmission. Reversing the direction of rotation can cause noise, impact, and increased wear due to the abrupt change in tooth engagement.

- Prone to Wear: The sliding contact between the gear teeth in spur gears can result in wear over time, especially under heavy loads or inadequate lubrication. Regular maintenance and proper lubrication are necessary to minimize wear and extend gear life.

It’s important to consider these advantages and disadvantages when selecting gear types for specific applications. While spur gears are well-suited for many applications, other gear types, such as helical gears or bevel gears, may be more suitable in certain situations depending on the requirements and operating conditions.

How do you choose the right size spur gear for your application?

Choosing the right size spur gear for your application requires careful consideration of various factors. Here’s a detailed explanation of the steps involved in selecting the appropriate size spur gear:

- Determine the Required Torque: Start by determining the torque requirements of your application. Calculate or estimate the maximum torque that the gear will need to transmit. Consider factors such as the power input, speed, and load conditions to determine the required torque.

- Identify the Speed Requirements: Determine the desired rotational speed or RPM (revolutions per minute) for your application. This will help in selecting a gear with the appropriate pitch diameter and tooth configuration to achieve the desired speed.

- Consider the Load Conditions: Evaluate the expected load conditions, including the magnitude and direction of the load. Determine if the load is constant or variable, and if it involves shock loads or cyclic loading. This will impact the gear’s durability and load-carrying capacity.

- Calculate the Pitch Diameter: Based on the torque and speed requirements, calculate the pitch diameter of the spur gear. The pitch diameter is determined by the formula: Pitch Diameter = (2 x Torque) / (Pressure Angle x Allowable Tooth Shear Stress).

- Select the Module Size: Choose an appropriate module size based on the gear size and application requirements. The module size determines the tooth size and spacing. Smaller module sizes are used for fine tooth profiles and higher precision, while larger module sizes are suitable for heavier loads and higher torque applications.

- Determine the Number of Teeth: Based on the pitch diameter and module size, calculate the number of teeth required for the gear. Ensure that the gear has an adequate number of teeth for smooth operation, load distribution, and sufficient contact ratio.

- Consider Space Constraints: Evaluate the available space and mounting requirements in your application. Ensure that the selected gear size can fit within the available space and can be properly mounted on the shaft or gearbox.

- Choose the Material: Consider the operating conditions, such as temperature, humidity, and presence of corrosive substances, to select the appropriate material for the spur gear. Common materials include steel, cast iron, brass, and plastic. Choose a material that offers the necessary strength, wear resistance, and durability for your specific application.

- Consider Additional Design Features: Depending on your application requirements, you may need to consider additional design features such as profile shift, hub configuration, and surface treatments. Profile shift can optimize gear performance, while specific hub configurations and surface treatments may be necessary for proper mounting and enhanced durability.

It’s important to note that gear selection is a complex process, and it may require consultation with gear manufacturers or experts in the field. They can provide guidance based on their expertise and assist in selecting the most suitable spur gear for your specific application.

By thoroughly considering factors such as torque requirements, speed, load conditions, pitch diameter, module size, number of teeth, space constraints, material selection, and additional design features, you can choose the right size spur gear that meets the demands of your application in terms of performance, durability, and efficiency.

editor by CX 2024-01-04